|

Tube and Pipe solutions Materials processed in the tube and pipe industry:

Click here to download a pdf on tube scarf chopping solutions. The three

main culprits for lost time accidents in welded tube production are injury

by crushing, injury by burns, and injury by cuts & abrasions.

These direct injury conditions are swiftly followed by indirect back

and shoulder injury created by repetitive motion and awkward lifting. When

one needs to extend their arms above shoulder height and pull the typical

wound up OD bead scrap ball off the winder then turn to throw the hot, sharp

object into the scrap container, injury becomes almost inevitable. Yet we

see this almost every day in most welded tube operations.

A typical shoulder injury can put an employee out of work for a week

or more. Burns and cuts can be

even more dramatic. In the end, both the employee and the company looses. It doesn’t have to be this way. There is a solution that is proven, by multiple installations, to reduce exposure to these major injury conditions. Feeding hot scarf to an inline chopper eliminates repetitive threading, eliminates scrap ball handling and gets the operator away from the moving scarf streams. Reduced exposure greatly minimizes the chance of injury, and the complete elimination of scrap ball handling does away with shoulder and back injuries. With the scarf-handling problem solved, the operator actually has more time to oversee the operation of the tube mill. Who doesn’t need more time today? Customers expect better quality; quality takes attention to detail and time. Not having to run to the scarf station every 10 minutes to dump the scrap ball and rethread the line means less interruptions in process control. Better quality without more stress or adding people.

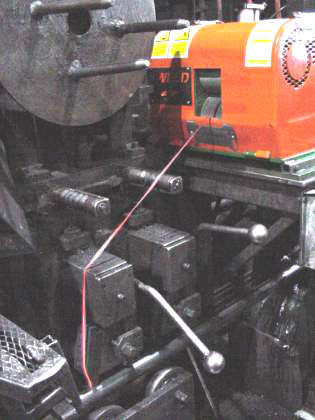

Simple integration. The SWEED OD Bead chopper mounts in about the same location as the scarf winder. Some installations are possible where both devices may be left on line. Once the operator gets used to the new process they do not want to go back to using the old winder.

Another

installation, one of two units installed in one plant. Note the incline chute base. Chopped scarf is directed towards the rear of the mill and into the scrap hopper by gravity. Not all installation can be arranged as shown. There are no two identical installations; all units must be adapted to fit the surrounding equipment.

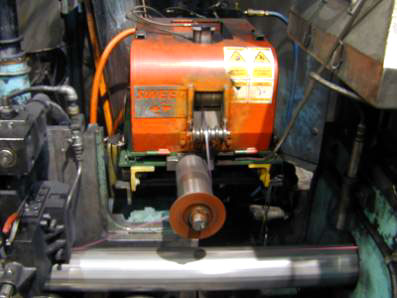

Another installation

chopping pre-galvanized tube OD scarf.

The scrap chute in this installation is directed towards the rear of

the mill and down stream to clear the HF weld power supply.

Installation at 90

degrees to tube travel.

This installation

has been in operation for over three years.

Note the magnetic conveyor bringing chopped scarf to the scrap

container. Chopped scarf is

directed by a chute via gravity to the magnetic conveyor which is then

pulled under the mill operator platform and dropped into the scrap

container.

O.D. and I.D. scarf, tube crushing and chopping systems. Contact us for specific applications. These applications are engineered to fit your particular line speed and programmed equipment. Removing, and disposing of tube scarf is a tricky and dangerous business. I.D. and O.D. tube scarf is a very hard material, with very sharp, jagged edges. Tube scarf is softer when it is hot, (can you say brand and cut) but is still a hazardous risk for the mill operator to contend with. The "scarf balls" are heavy, hot, and sharp! Sweed Choppers handle the grueling job of tube scarf processing. Quit your "winding" and get a Sweed scrap chopper!

An OD scarf chopper

To play a video clip of an OD scarf chopper in operation, select one of the links below. Sweed TS450 short video clip MPG file size - 475 KB Sweed TS450 long video clip WMV file size - 4 MB

Typical "scarf ball" and mill operator "losing his shirt" to the scarf.

Scarf that has been processed through a Sweed chopper. The pieces are about 3" long. Contact Us for more information. |